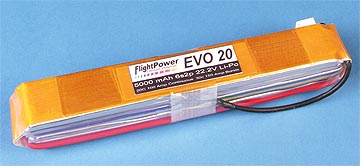

High energy, lightweight batteries

Flight Power " EVO 20" Lithium Polymer battery, from http://www.hobby-lobby.com

Lithium Sulphide battery from http://www.edn.com/blog/Anablog/38373-Solar_plane_with_lithium_sulfur_batteries.php

High energy density batteries

We consider the two top battery technologies: the latest Lithium Polymer technology, and the up and coming Lithium Sulphide battery technology.

Lithium polymer ("LiPo") batteries

Cells sold today as polymer batteries are pouch cells. Unlike lithium-ion cylindrical cells, which have a rigid metal case, pouch cells have a flexible, foil-type (polymer laminate) case. In cylindrical cells, the rigid case presses the electrodes and the separator onto each other; whereas in polymer cells this external pressure is not required (nor often used) because the electrode sheets and the separator sheets are laminated onto each other. Since individual pouch cells have no strong metal casing, by themselves they are over 20% lighter than equivalent cylindrical cells.

The voltage of a Li-poly cell varies from about 2.7 V (discharged) to about 4.23 V (fully charged), and Li-poly cells have to be protected from overcharge by limiting the applied voltage to no more than 4.235 V per cell used in a series combination.

Early in its development, lithium polymer technology had problems with high internal resistance. Other challenges included longer charge times and lower maximum discharge rates compared to more mature technologies. In December 2007 Toshiba announced a new design offering a much faster rate of charge (about 5 minutes to reach 90%). These cells were released onto the market in March 2008 and were expected to have a dramatic effect on the power tool and electric vehicle industries, and a major effect on consumer electronics.[3] Recent design improvements have increased maximum discharge currents from 2 times to 65 or even 90 times the cell capacity charge per hour.

In recent years, manufacturers have been declaring upwards of 500 charge-discharge cycles before the capacity drops to 80% (see Sanyo). Another variant of Li-poly cells, the "thin film rechargeable lithium battery", has been shown to provide more than 10,000 cycles.

from http://en.wikipedia.org/wiki/Lithium_polymer_battery

Lithium Sulphide batteries

Sion Power has achieved breakthrough results by a unique merging of sulfur and lithium chemistries, to develop Li-STM technology. Sion Power uses the well-known high electrochemical potential of lithium and combines it with sulfur, to attain a superior rechargeable performance. Theoretical specific energy is in excess of 2,500 watt hours per kilogram and energy density exceeded 2,600 watt hours per litre.

By using the powerful combination of the elements, lithium and sulfur, in the most efficient geometry, a thin-film sandwich, Sion Power has created a rechargeable battery with advanced characteristics. Sion Power's Li-S technology provides rechargeable cells with a specific energy of over 350 Wh/kg, which is 50% greater than the currently commercially available rechargeable battery technologies. Over 600 Wh/kg in specific energy and 600 Wh/l in energy density, are achievable in the near future.

This unique chemistry can be designed to deliver high energy, high power, or, a combination, depending upon the requirements of the application. For example, in high power applications like power tools and appliances, Li-S has nearly the same rate capability as nickel cadmium and nickel metal hydride but has only one-third to one-fourth the weight. Furthermore, Sion Power cells have a voltage of 2.1 volts, which is ideal for the next generation of electronics, expected to operate at 2 volts or less. For higher voltages, the cells can be easily connected, in series.

Lithium Sulphur technology

Li-STM is both cost effective and cost competitive, when compared to other battery systems Battery costs are driven primarily by the material content and yield. As sulfur is much less expensive than the typical components of other battery systems, the Li-STM technology starts with a lower material cost than lithium-ion or lithium-polymer batteries. Manufacturing techniques for Li-S batteries are very similar to those used in other battery chemistries.

Ease of Production

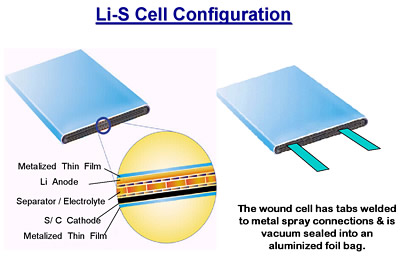

Manufacturing of Li-STM cells is no more difficult than manufacturing lithium-ion liquid, or, lithium-ion polymer cells. The anode and cathode of Li-STM cells are thin materials, substantially similar in thickness and tensile strength to those of lithium-ion. Standard lithium-ion winders can be used with little or no modifications. Prismatic and cylindrical form factors can be produced from the same anode and cathode raw materials.

The Company's technology is secured by over 51 US issued patents and over 48 applications pending worldwide, protecting various enabling aspects of Sion Power's intellectual property. Sion Power’s Li-S is the next rechargeable power source for a wide variety of applications, including unmanned vehicle systems, military communications, cell phones, notebook pcs and electric vehicles.