Two stroke engines

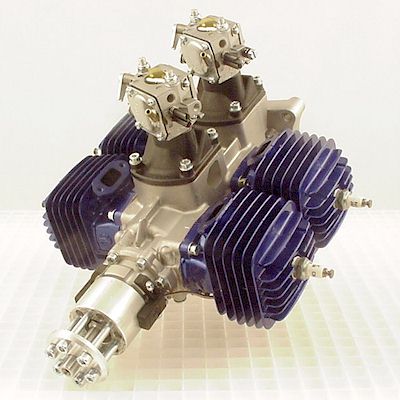

OS Engines BGX-1 3500 RN engine from www.osengines.com

In general, two stroke engines have an excellent power-to-weight ratio, and are relatively inexpensive. They are unfortunately also not very fuel efficient and exhibit high vibration and noise levels.

O.S. Engines: methanol powered

The 120AX 2 stroke engine from www.osengines.com

| engine type | weight in kg | power output in kWatts | kWatts / kg | J/ccfam |

|---|---|---|---|---|

| 91VR-DF | 0.662 | 3.58 at 22,000 rpm | 5.407 | 0.664 |

| 120AX | 0.650 | 2.31 at 9,000 rpm | 3.553 | 0.770 |

| 104RX | 0.830 | 2.61 at 9,000 rpm | 3.144 | 0.756 |

| 160FX | 0.925 | 2.76 at 9,000 rpm | 2.984 | 0.708 |

| BGX-1 3500 RN | 1.340 | 3.06 at 10,000 rpm | 2.282 | 0.525 |

Notes

- All O.S. engines use " glow fuel" : methanol + 5 to 15% nitromethane + 16% minimum synthetic castor oil lubricant.

- J/ccfam = energy in Joules per cc of fuel-air mixture

- J/ccfam = ( power_in_watts x 60 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

RCV Engines: methanol powered

RCV engine information from rcvengines.com

| capacity in cc | power output in kWatts | kW / kg | J/ccfam |

|---|---|---|---|

| 9.5 | 0.640 at 10,800 rpm | 1.28 | 0.748 |

| 15 | 1.120 at 9,900 rpm | 1.566 | 0.905 |

| 21.3 | 1.500 at 9,000 rpm | 1.507 | 0.939 |

Notes

- All RCV engines use " glow fuel" : methanol + 10 % nitromethane + 15% minimum synthetic castor oil lubricant.

- J/ccfam = energy in Joules per cc of fuel-air mixture

- For RCVxx-CD, J/ccfam = ( power_in_watts x 60 x 2 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

Cosworth engines: gasoline powered

from sae.org/aeromag/techupdate/09-2006/2-26-8-5.pdf

US Navy commissions Cosworth for heavy fuel UAV engine development

DATE 7 March 2008, SOURCE Flightglobal.com, By Rob Coppinger

UK engineering company Cosworth has been selected by the US Navy for the first of three phases of the two-year ultra endurance unmanned air vehicle (UE-UAV) heavy fuel engine technology development programme.

Cosworth plans to increase the power output of the 3 HP (2.23kW) AE-1 engine, which weighs 3.5 kg, during the four month-long first phase, as well as improving its fuel efficiency and reducing its noise levels. The power output increase, to the US Navy's target of up to 10 HP, is expected to require an increase in the AE-1's number of cylinders from one to two. The three phases include extensive ground and flight test evaluations of heavy fuel engines to prove their technological readiness.

Cosworth's aerospace and defence business unit leader Simon Corbyn says: "Development of a range of heavy-fuel UAV engines is a key requirement to alleviate the military's dependency on multiple fuels. In contrast heavy fuels such as diesel and jet fuels are routinely supported and significantly reduce risk."

If successful the engine will be used for the US Navy's Small Tactical Unmanned Aerial System, Tier Two class UAV programme. In the second and third quarters last year the AE-1, fuelled with diesel, was used to power the Arcturus T-16 UAV in test flights over California as part of the US Marine Corp's Tier Two tactical UAV concept demonstration programme. In rig tests at Cosworth's Northampton head office the AE-1 used a variety of heavy fuels.

Desert Air: gasoline powered

above and below from http://www.desertaircraft.com/engines_detail.php?Page=DA-100

| Measurement | DA-100 | DA-150 | units |

|---|---|---|---|

| displacement | 100 | 150 | cc |

| output power | 7.31 at 6,000 rpm | 12.3 at 6,000 rpm | kWatts |

| weight | 2.63 | 3.61 | kg |

| kWatts / kg | 2.78 | 3.407 | kWatts / kg |

| speed | 1,000 to 6,700 | 1,000 to 6,500 | rpm |

| max speed | 8,500 | 8,500 | rpm |

| fuel consumption | 71 at 6,000 rpm | 93.5 at 6,000 rpm | g / min |

| J/ccfam | 0.731 | 0.820 | J / cc |

Features

- Four petal reed valve, bottom induction.

- Desert Aircraft, auto advance, electronic ignition.

- Walbro Carburator

- Exclusive Desert Aircraft designed cylinders, pistons, and crankshaft.

- Three piece, CNC milled, 2024-T3 aluminum alloy crankcase.

- Low vibration. Most torque in its class.

- Long rod to stroke ratio.

- Aerobatic power curve.

- Three crank bearings.

Notes

- J/ccfam = energy in Joules per cc of fuel-air mixture

- J/ccfam = ( power_in_watts x 60 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

Evolution Engines: gasoline powered

Evolution engines 116 Gx 2, from evolutionengines.com

| weight in kg | power output in kWatts | kWatts / kg | J/ccfam |

|---|---|---|---|

| 0.936 | 2.795 at 9,000 rpm | 2.986 | 0.731 |

| 1.493 | 3.015 at 8,500 rpm | 2.019 | 0.615 |

| 1.290 | 3.825 at 6,200 rpm | 2.965 | 0.861 |

| 1.820 | 6.338 at 6,950 rpm | 3.482 | 0.940 |

| 3.090 | 8.090 at 5,900 rpm | 2.618 | 0.709 |

Notes

- All Evolution engines use a gasoline : oil mixture in a 40 : 1 ratio of gasoline : oil

- Only the EVOE116GX is a two cylinder engine

- J/ccfam = energy in Joules per cc of fuel-air mixture

- J/ccfam = ( power_in_watts x 60 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

Graupner: gasoline powered

Graupner G 26 engine from graupner.de

| weight in kg | power output in kWatts | kWatts / kg | J/ccfam |

|---|---|---|---|

| 1.100 | 2.8 at 7,500 rpm | 2.545 | 0.861 |

| 1.630 | 6.338 at 6,950 rpm | 3.888 | 0.943 |

Notes

- All Graupner engines use a gasoline : oil mixture in a 40 : 1 to 50 : 1 ratio of gasoline : oil

- J/ccfam = energy in Joules per cc of fuel-air mixture

- J/ccfam = ( power_in_watts x 60 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

These engines have been developed and built specifically for model flying by a team of specialists. Both engines feature multiple ballraces. The electronic ignition system with integral retard makes the engines very easy to start, and no great force is required. The G 26 is an ideal power plant for two-metre class aerobatic models. The G 57 might well be the lightest high-torque engine in its class, making it an excellent option for F3A-X models. However, it is also a fine choice for other power models weighing up to 13 kg all-up, and for aero-towing tugs of similar weight and up to 2.80 m span.

The G 57 in particular incorporates technologies and manufacturing processes developed for F-1 racing, and both engines have been subjected to an extended programme of static and practical testing. In conjunction with suitable exhaust systems these engines develop a level of power which is normally the province of engines of much greater swept capacity.

The engines are operated using a petrol / oil mix (2-stroke mixture, 1 : 50), while a 4-cell battery of at least 800 mAh capacity is required for the ignition system. The set includes operating instructions, ignition system, propeller fixings and exhaust gasket. We recommend that these engines should be run using the exhaust systems developed specially for them.

from shop.graupner.de

Modellmotoren: gasoline powered

| engine | capacity in cc | weight in kg | power out in kWatts | kW per kg | max rpm | J/ccfam |

|---|---|---|---|---|---|---|

| 3W-28i CS | 28.5 | 1.211 | 2.35 | 1.94 | 8,500 | 0.582 |

| 3W-55i CS | 53.3 | 1.937 | 4.27 | 2.2 | 8,500 | 0.565 |

| 3W-75i CS | 75.2 | 2.454 | 5.88 | 2.396 | 8,500 | 0.552 |

| 3W-106i CS | 106 | 2.867 | 9.19 | 3.205 | 8,500 | 0.612 |

| 3W-157 XI B2 CS | 157 | 4.114 | 14.34 | 3.486 | 8,500 | 0.645 |

| 3W-200i B2 TS CS | 201 | 4.767 | 15.3 | 3.21 | 7,500 | 0.609 |

| 3W-212i B4 CS | 212 | 5.720 | 15.8 | 2.762 | 7,500 | 0.596 |

Notes

- All Modellmotoren motors use petrol : lubricant in a 1:50 to 1:80 mix ratio.

- J/ccfam = energy in Joules per cc of fuel-air mixture

- J/ccfam = ( power_in_watts x 60 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

ROTO engines: gasoline powered

Two cylinder ROTO 70 V2 from rotomotor.cz

| weight in kg | power output in kWatts | comments |

|---|---|---|

| 1.62 | 2.942 at 8,000 rpm | 1 cylinder |

| 1.8 | 2 cylinder | |

| 2.3 | 2 cylinder |

Notes

- All ROTO engines use petrol (gasoline) + "OIL MOTUL 600" in a 1:50 ratio.

Zenoah gasoline powered engines by Husqvarna

from www.zenoah.net

| engine | gross power in kWatts | kWatts / kg | rpm for max power | J/ccfam |

|---|---|---|---|---|

| G260PU | 2.13 | 1.20 | 11,500 | 0.437 |

| G380PU | 2.06 | 1.03 | 8,500 | 0.389 |

| G450PU | 2.9 | 1.35 | 8,000 | 0.483 |

| G620PU | 4.0 | 1.70 | 9,000 | 0.430 |

| G800BPU | 5.51 | 1.53 | 8,500 | 0.486 |

Notes

- All Zenoah engines use pre-mixed fuel, 25 (Gasoline) : 1 (high grade 2 cycle engine oil)

- J/ccfam = energy in Joules per cc of fuel-air mixture

- J/ccfam = ( power_in_watts x 60 ) / (capacity_in_cc x rpm ) = measure of energy efficiency

Engine trends for the above mentioned 2 stroke engines

From the above plot, we deduce a linear output power scaling with engine capacity of 76 Watts per cc for the Modellmotoren engines. Note that the top three points for the Modellmotoren engines are for multi-cylinder engines (actually 2, 2 and 4 cylinder engines respectively).

Note that the largest engine is a four cylinder motor: hence the lower power-to-weight ratio. We have left off the very high revving OS Engines 91VR-DF for ducted fans with a massive power-to-weight ratio of 5.407 kWatts / kg. If we ignore the Zenoah engines with their low power-to-weight ratios, we get an average power-to-weight ratio of 2.8926 kWatts / kg.

We calculate an average engine efficiency of 0.654 J/ccfam for all of the above engines.